Tire Recycling Helps Avoid Harmful Emissions

An ongoing study confirms that tire recycling avoids harmful emissions when compared to the impacts of using new materials to create the same products.

Read the most current LCA Report for eTracks tire recycling efforts: Scrap Tire Life Cycle Assessment (updated to include 2021 and 2022 data)

Meeting producer obligations under Ontario’s Resource Recovery and Circular Economy Act (RRCEA) and Tire Regulation 225/18 means providing services to producers that ensure they meet their regulatory target to collect and recycle 100 per cent of the used tires they sell into the marketplace. This includes transporting them to processing facilities and verifying how they are repurposed into new products for approved use in the marketplace as a Tire Derived Product (TDP). A TDP displaces the more conventional use of new, or “raw” materials used to make products.

People expect that products made from recycled tires will deliver ecological benefits when compared to the use of (new) materials they displace. Putting numbers to this expectation was at the heart of the “Scrap Tire Life Cycle Assessment (LCA),” an benchmark study that involves the elective participation of seven members of the Canadian Association of Tire Recycling Agencies (CATRA). The current study includes collection and analysis of participating tire recycling agencies using data spanning 2019 – 2022, and each year, participants receive their updated individual LCA report. The engagement of a critical review panel ensured that the methodology of analysis and reporting aligns with the requirements of the International Organization for Standardization (ISO 14044).

What is an ISO Critical Review?

The LCA report underwent the critical review process in accordance with ISO standards. The purpose of a critical review is to ensure studies are performed in a manner consistent with ISO methodology and best practices, and that the conclusions of a report are supported by the data used. The LCA review found that the report was in conformance with ISO standards, the methods used to carry out the LCA are scientifically valid, and the findings are supported by the information presented. Note: the provincial model and findings for Ontario were included in the scope of the critical review, the individual provincial report was not.

The following summary of the life cycle assessment focuses on data provided by eTracks Tire Management Systems for its 2020 tire recycling activities in Ontario including: used tire collection, hauling, processing and repurposing activities.

Study Overview of Results from 2017 – 2020

The LCA study looks through a lens of six environmental impacts, including: global warming (climate change), smog, air particulates (human health particulates), acidification, ozone depletion, and air and water eutrophication. Results show how a TDP fares, in each of these categories, when compared to the life cycle impacts of its respective displaced material. Results also show how each TDP compares with another when it comes to ecological impacts. For each of these ecological impacts, the magnitude of avoided impacts in Ontario were at least twice the magnitude of those where new materials were used, with scores for climate change/global warming, human health (air) particulates and acidification being particularly favourable.

The six impact categories used in the study measured the emission impacts of tire recycling activities, in comparison to the emissions that would have been created if making the same TDP from new/raw materials in 2020:

(Numbers have been rounded up/down as appropriate.)

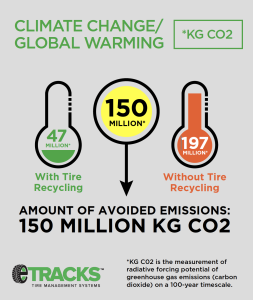

Tire recycling reduced the impact of CO2 emissions into the environment by 150 million kg C02 in 2020.

Climate Change/Global Warming (kg C02): indicates the radiative forcing potential of greenhouse gas emissions (carbon dioxide) on a 100-year timescale. i.e. With tire recycling activities: 47,000,000 kg C02 impacts, vs. without tire recycling activities: 197,000,000 kg C02. Total amount of avoided emissions:150,000,000 kg C02

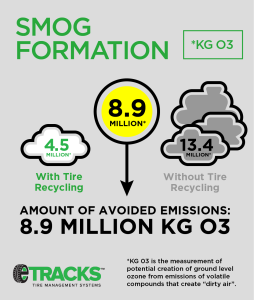

Smog Formation (kg 03): indicates the potential creation of ground level ozone from emissions of volatile compounds that create “dirty air”. i.e. With tire recycling activities: 4,500,000 kg O3, vs. without tire recycling activities: 13,400,000 kg 03. Total amount of avoided emissions: 8,900,000 kg O3

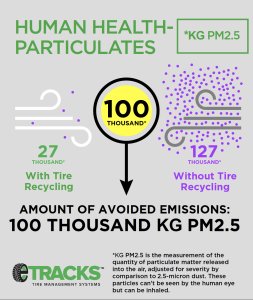

Tire recycling reduced the impact of human health particulates by 100 thousand kg PM2.5 in 2020.

Human Health-Particulates (kg PM2.5): indicates the quantity of particulate matter released into the air, adjusted for severity by comparison to 2.5-micron dust. These particles can’t be seen by the human eye but can be inhaled. i.e. With tire recycling activities: 27,000 kg PM2.5, vs. without tire recycling activities: 127,000 kg PM2.5. Total amount of avoided emissions: 100,000 kg PM2.5

Acidification (kg S02): reports emission of compounds that contribute to increased acidity in the air, either by droplet or particle. i.e. With tire recycling activities: 210,000 kg S02, vs. without tire recycling activities 850,000 kg S02. Total amount of avoided emissions: 640,000 kg S02

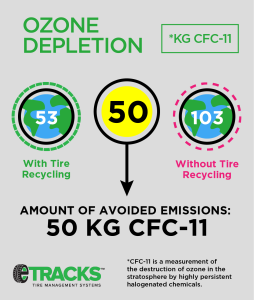

Ozone Depletion (kg CFC-11): describes the destruction of ozone in the stratosphere by highly persistent halogenated chemicals. i.e. With tire recycling activities: 53 kg CFC-11, vs. without tire recycling activities: 103 kg CFC-11. Total amount of avoided emissions: 50 CFC-11

Tire recycling reduced acidification emissions in Ontario by 640 thousand kg S02 in 2020.

Eutrophication (kg N): reports environmental emissions of compounds containing nitrogen and phosphorus, which can destabilize aquatic ecosystems. i.e. With tire recycling activities: 22,000 kg N, v. without tire recycling activities: 45,000 kg N. Total amount of avoided emissions: 23,000 kg N

Source: Scope 3 Consulting LLC (2022), Scrap Tire Recovery and Recycling in Ontario: CATRA 2021 Scrap Tire Life Cycle Assessment, Version 2.2

Tire recycling reduced emissions that cause smog formation in Ontario by 8.9 million kg of o3 in 2020.

The Products Most Effective in Reducing Emissions

Of the twenty-one TDPs created from used tires, seventeen of them resulted in a net reduction of Green House Gas (GHG) emissions. Products that were most effective in reducing emissions in Ontario include: re-use of used tires, re-treading used tires, crumb rubber (including fiber and acrylic sand), rubberized asphalt, moulded rubber, moulded concrete and blast mats.

“With a regulatory target of 100% tire collection and recycling, Ontarian’s benefit from Extended Producer Responsibility (EPR); the reduction in emissions shown in this study are proof of that. The broader challenge for industry players is to improve our technologies and recycling systems, such that it’s easy and practical to repurpose materials, instead of sourcing new materials. Ontario continues to move towards sustainable goals and we’re excited to be a part of that – building better recycling systems, removing valuable materials from waste streams and putting them back into use for as long as possible,” says Steve Meldrum, CEO, eTracks Tire Management Systems.

Tire Recycling reduced emissions associated with ozone depletion in Ontario by 50 kg CFC-11 in 2020.

Study Background

The study was developed by California-based Scope 3 Consulting LLC with the goal of establishing a boundary for analysis around end-of-life tire management systems that begin when used tires are first returned to a tire collection site (e.g. tire shops). The impacts of transporting the tires and processing them into a TDP are compared to the impacts of producing conventional non-tire-derived products. Widely accepted industry data sources were employed for the task of assigning quantitative ecological impacts for the life cycle of each TDP and its respective displaced product, these impacts are calculated to the point at which the material is ready for delivery to its end-use. In Ontario, this is referred to as “approved use” and “recovery”. It is the point at which a used tire has been made into a new product, such as, livestock mats, playground flooring, and/or rubberized asphalt and concrete. The Ontario report represents a combination of data collected from the Ontario Tire Stewardship (OTS) archives (2017-2018) the Resource Productivity & Recovery Authority (RPRA)(2019) and eTracks Tire Management Systems (2020)

Results Inform Decisions

eTracks is a private company that offers services to Ontario tire producers by assisting them in meeting or exceeding their regulatory obligations to collect, recycle and repurpose the used tires they sell into the marketplace. With this verified knowledge, eTracks and its customers can demonstrate the value of recycling and repurposing initiatives to effectively reduce negative environmental impacts. The study results also invite us to consider the ecological implications, along with many other factors that go into planning, decision-making and meeting compliance obligations.

The Circular Economy and Tire Recycling

The circular economy is an approach to utilizing our resources in such a way that we increase their life-span, reduce waste and innovate to lengthen the life cycle of the materials and products we use everyday. To achieve this requires the active participation of all of us: consumers, industry leaders and government – working together to develop strategies for increasing the sustainability of our systems. The circular economy, and models such as Individual Producer Responsibility (IPR) and Extended Producer Responsibility (EPR), look beyond resource use and efficiency alone and also consider the impact of resource use on Green House Gas (GHG) emissions. Visit our Resources page to learn more about IPR, EPR and Ontario’s circular economy.

Tire recycling reduced emissions that can affect aquatic systems 23 thousand kg N in 2020.

If you have questions about the Ontario report, please contact Melissa Carlaw, Director of Communications and Marketing at mcarlaw@etracks.ca

More information summarizing the results achieved by participating CATRA members will be shared on the CATRA website in the coming weeks.

About eTracks: eTracks was incorporated under the Canada Not-For-Profit Corporations Act in 2017 and is governed by an independent Board of Directors. The company was originally created by the Tire and Rubber Association of Canada (TRAC) to meet the needs of TRAC members and other obligated tire producers under the Resource Recovery and Circular Economy Act (RRCEA) in Ontario. Since then, eTracks has helped shape Ontario’s recycling industry to become known as a trusted, innovative, industry leader in Ontario’s circular economy. Our purpose as a Producer Responsibility Organization (PRO), and one we are proud of, is our commitment to managing recyclable materials, and corresponding supply chains in a responsible, reliable and fair manner. eTracks has the experience and the ability to support other materials classes as they transition to individual or extended producer responsibility models, supporting systems in moving from waste to resource models to create a more circular economy for future generations.